You can use our job cost calculator to determine the material and labor costs of an animal guard install, as well as the cost savings of an AG Bender™

Solar Animal Guard Job Cost Calculator

You can use our job cost calculator to determine the material and labor costs of an animal guard install, as well as the cost savings of an AG Bender™

We crunch the numbers on pest-related maintenance costs of solar PV; and share a model that homeowners, installers and investors can use to calculate their own risk.

Animal Guard Benders are built to last. Hear what Davis at Namasté Solar has to say about his tool.

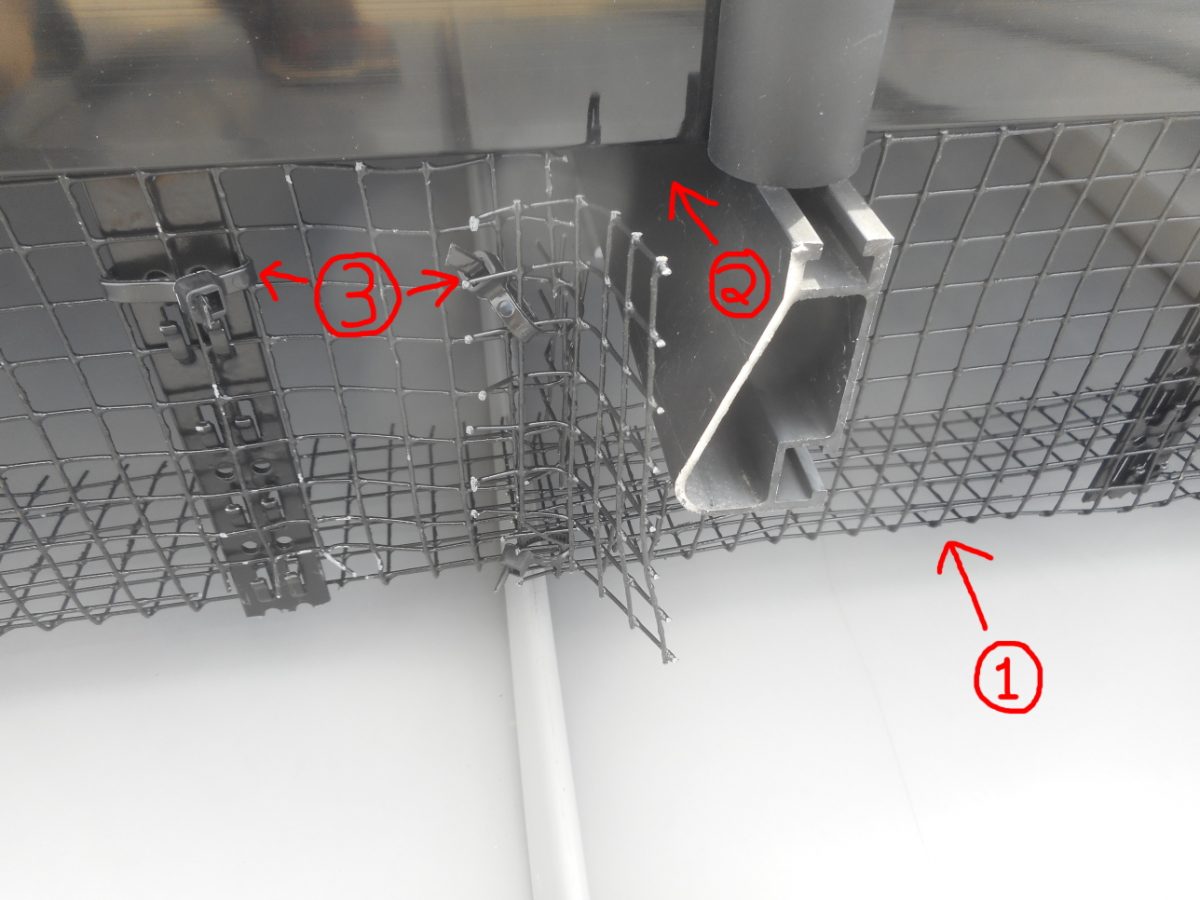

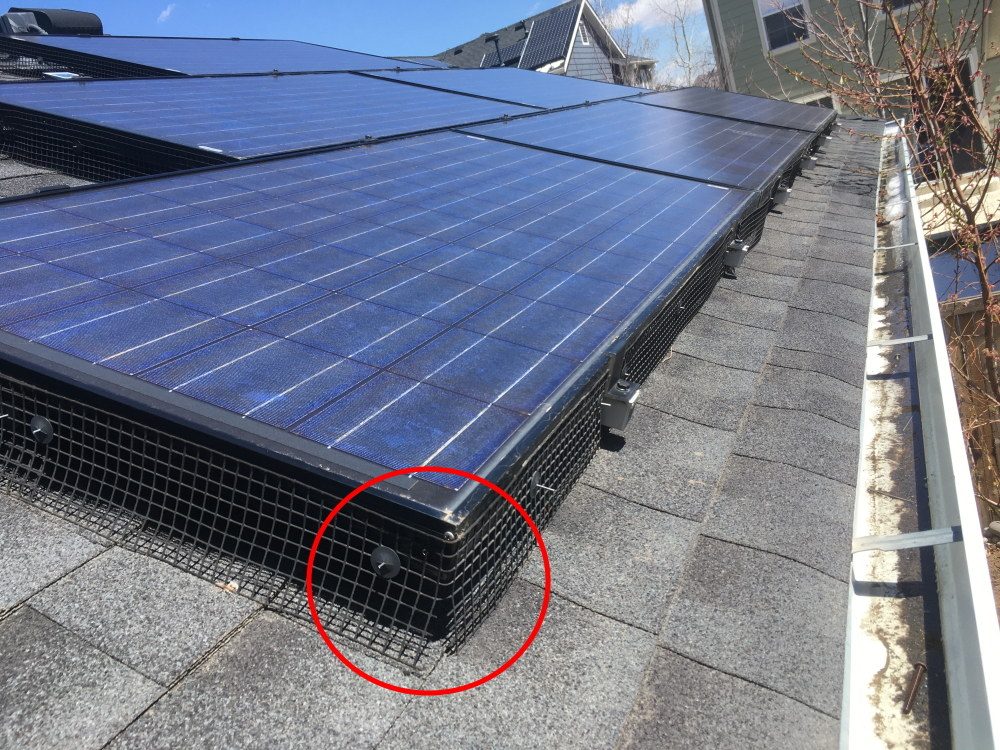

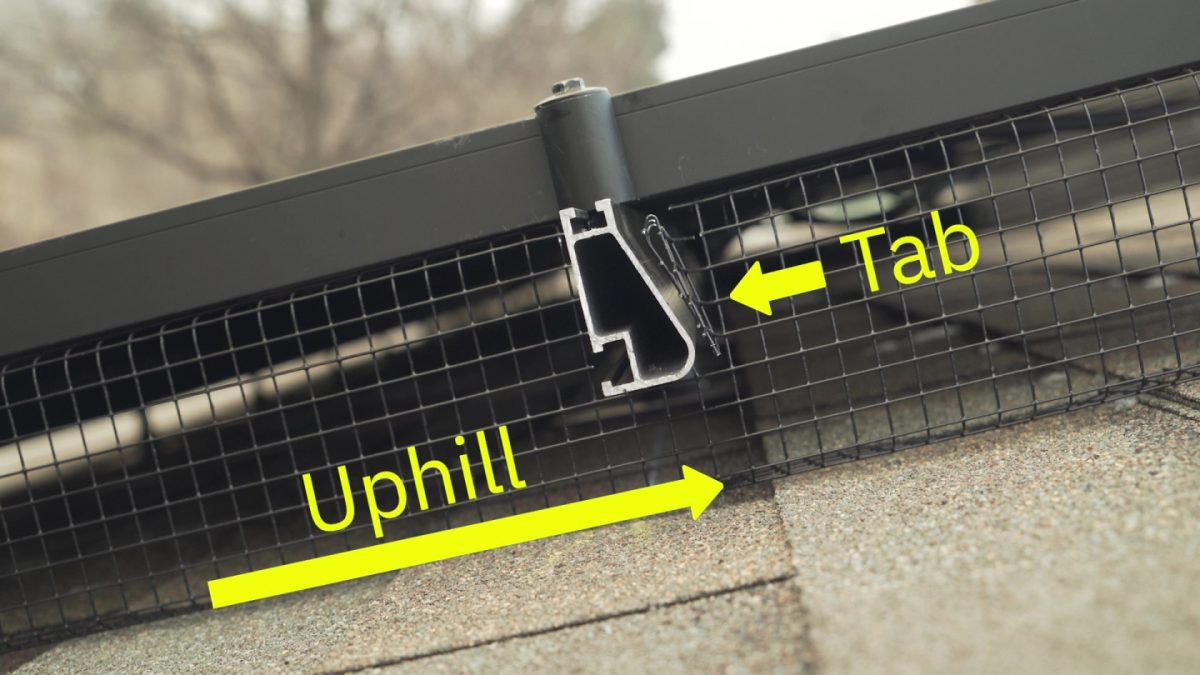

Getting a tight, critter-proof seal around your PV array is easier said than done! See photos of common mistakes and learn how to handle tricky racking and roof types (did someone say tiles?)

Learn why animal guard often fails at the corners of a PV array, and what to do about it!

Our new instruction video shows installers and homeowners alike how to install solar animal guard.

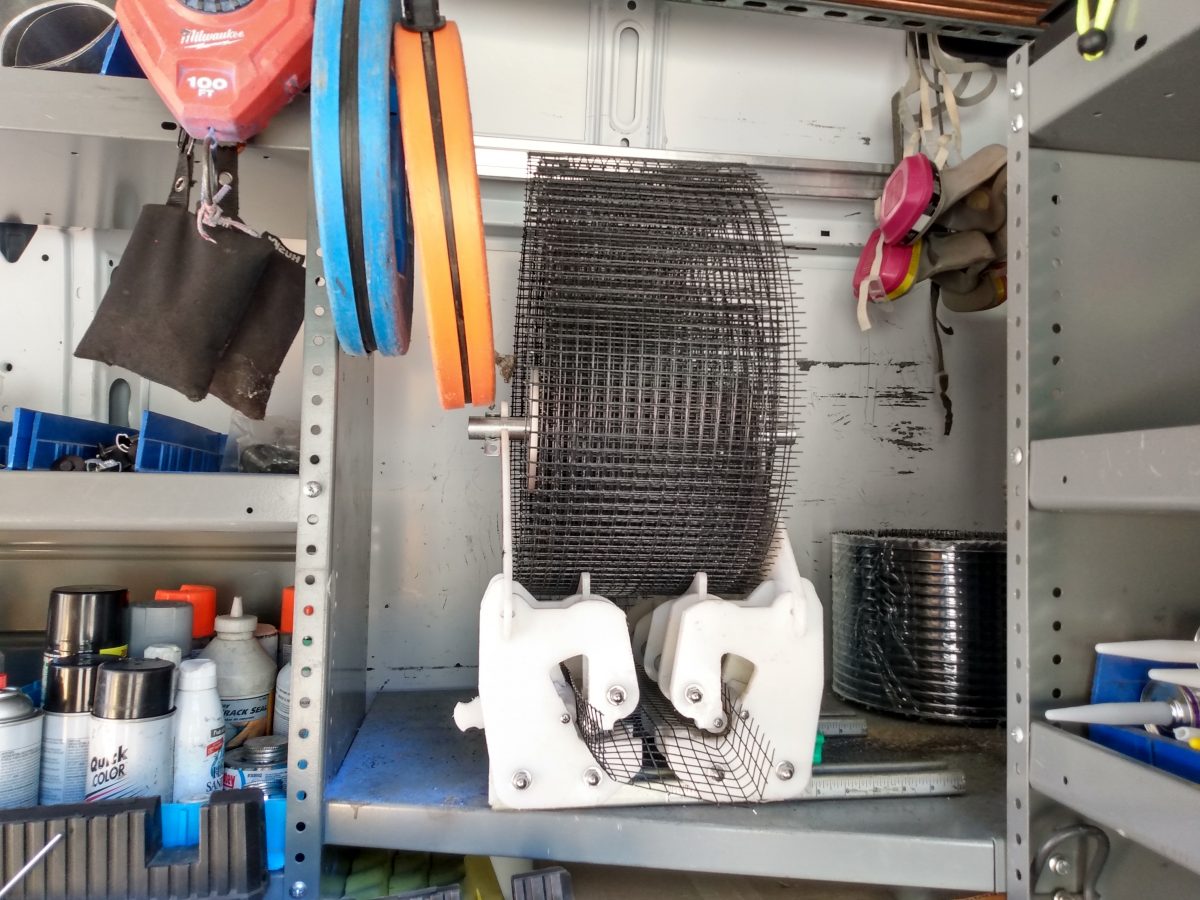

Solar installers and homeowners now have a comprehensive guide to the best materials and tools for solar animal guard.

When deciding how to protect a solar PV system from pest incursion, it’s helpful to understand exactly what’s at stake. We dig into the most common forms of damage seen in the field, complete with juicy photos!