Page Contents

While installer technique is the key to effective animal guard, it doesn’t hurt to start with the right tools and materials! Use this page to find supplies that fit your budget and job volume. Our recommendations are informed by solar technicians who’ve seen how each item holds up after years in the field.

What makes a good wire mesh for solar critter guard / birdproofing?

Click a topic below to learn more

Opening size

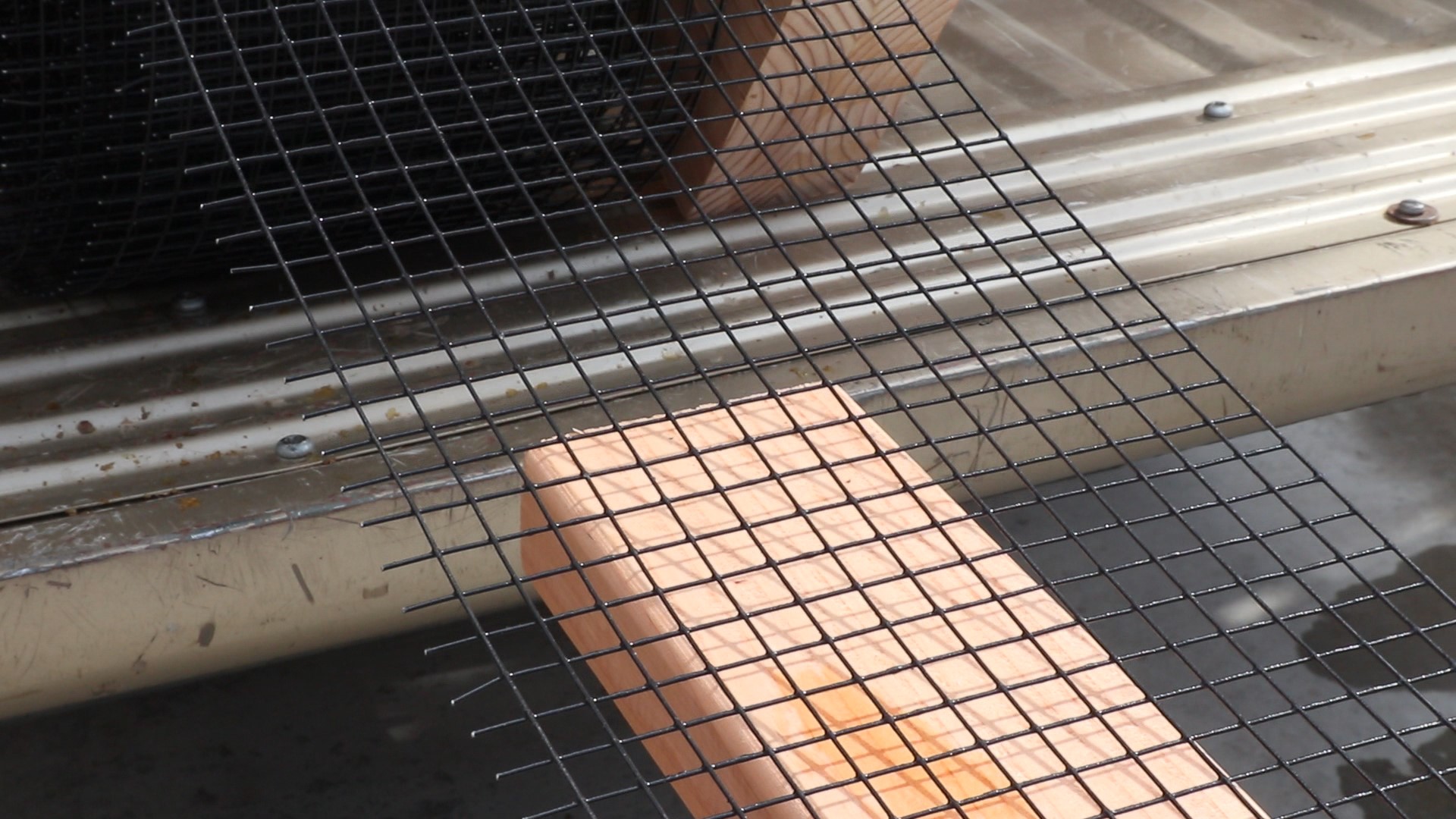

The larger the openings (space between wires), the bigger the critters which will have access to the solar array. The industry has coalesced around a maximum opening size of 1/2″, which blocks most critters without restricting airflow. 1/2″ wire mesh is sometimes called 2×2 mesh or #2 mesh.

Wire gauge and stiffness

A wire gauge of AWG 19 (about .04″ in diameter) is recommended for long-term durability. Note this is significantly thicker than chicken wire and will hold its shape once bent.

Note that galvanization (see “corrosion resistance,” below) also affects wire stiffness and strength. Wire mesh sold without galvanization will be much softer and less springy than galvanized mesh. We do NOT recommend non-galvanized mesh.

Corrosion resistance

We recommend only galvanized, plastic-coated wire mesh. These two treatments should allow the mesh to last the lifetime of the PV system (despite some light cosmetic rust). Go with a well established manufacturer, since there is no easy way to judge the quality of these treatments on sight. The image at right shows a poor-quality wire mesh which rusted prematurely.

Wire meshes can be galvanized with two different techniques – Hot-Dip and Electroplating. Hot-dip galvanization forms a much thicker and more resilient barrier to moisture.

Available widths and lengths

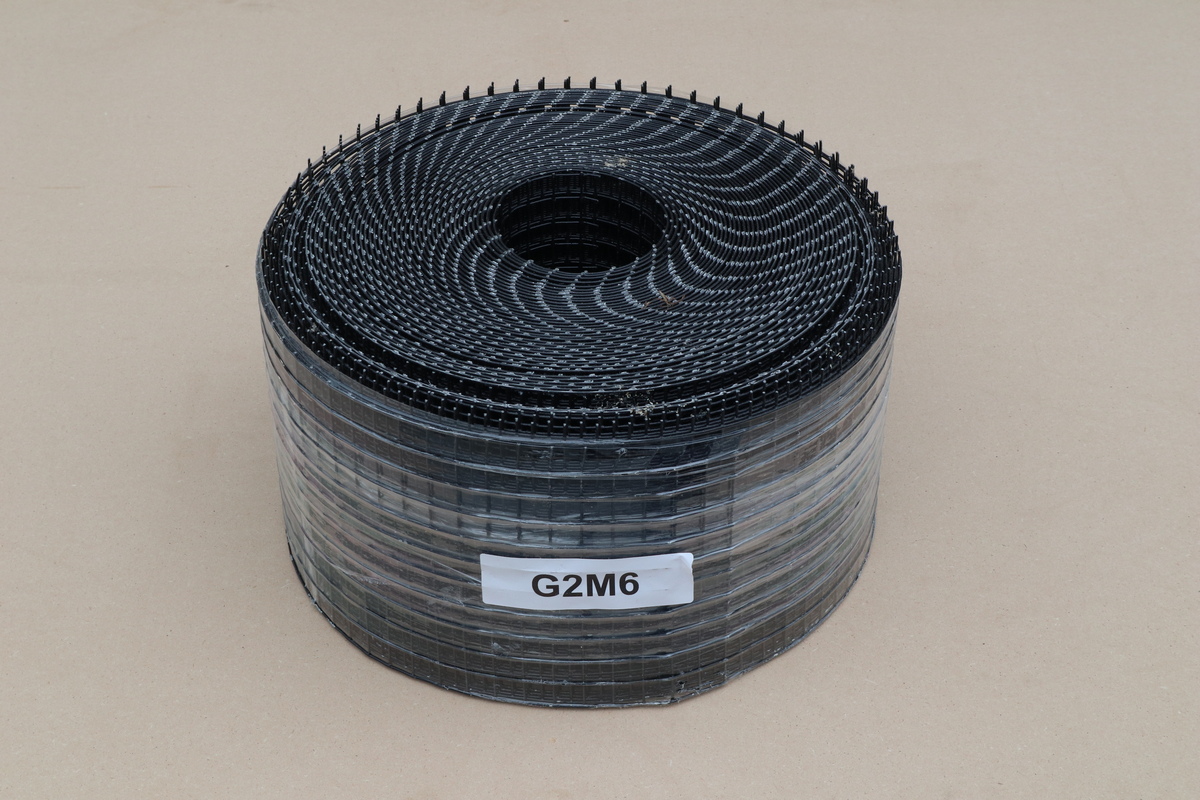

A typical residential PV array requires between 100 and 300 feet of wire mesh to enclose. Wire mesh is typically sold in 100-foot rolls, but some distributors cut it into shorter lengths (usually at a significant per-foot markup). The wire mesh width needed for a particular PV array depends on the racking system and installation method – but the most common are 4″, 6″ and 8″.

Open screening area (OSA)

OSA is the percentage of a screen’s total area which allows air to pass through. A high OSA (say 90%) allows good ventilation; picture a screen with very thin wires and big openings. A low OSA (say 70%) allows air to pass through only 70% of its area, leading to high array temperatures and poor PV performance.

| Screen Type | Specification | Open Screening Area |

|---|---|---|

Typical AG wire mesh | No. 2 mesh, 19 gauge, galvanized & coated | 81% |

Window Screen | No. 16 mesh, 29 gauge | 68% |

Solatrim | Perforated sheet metal | 45% |

PVC vs polyester (AKA powder) coating

Please see our separate article on this important distinction!

The Best PVC-Coated Wire Mesh for Solar Animal Guard

Slick Tools Heavy Duty Solar Panel Squirrel & Bird Guard Fence

Slick Tools now sells good quality wire mesh through our online shop! It meets all the criteria described above and has been used on thousands of PV systems. Our pricing is competitive for both individuals and high-volume solar installers. Finally, our mesh is guaranteed to be compatible with the AG Bender for ultra-fast installation. Learn more at our wire mesh product page.

All Wire Meshes

| Vendor | $/foot @ 6″ width* | $/foot @ 8″ width* | Available widths | Available lengths |

|---|---|---|---|---|

| Slick Tools | $.58 | $.65 | 4″, 6″, 8″, 10″ | 100′ |

| TWP Inc. | $.56-$.70 | $.68-$.85 | 6″, 8″ | 100′ |

| Spiffy Solar | $.86 | $.99 | 4″, 6″, 8″ | 100′ |

| Heyco | $.86 | $1.05 | 4″, 6″, 8″ | 100′ |

| SolaTrim | $4.80 | $4.80-$5.68 | 5.5″, 6.75″ | 25′, 100′ |

**Not all widths shown on manufacturer website; contact them for a quote.

Wire Mesh Alternative – SolaTrim

SolaTrim makes the only purpose-built sheet metal pest barrier on the market. The product comes in pre-cut panels and uses a preinstalled adhesive tape to attach to the solar panel frame. While we think this is a cool product that may work well in some scenarios, we have a few hesitations:

- We’re concerned about airflow restriction increasing under-array temperatures and reducing PV performance. See the note above on Open Screening Area.

- Several installers in both very-hot and very-cold climates have told us the adhesive does not stick well under those conditions.

- If solar panels must be lifted up for service, it appears the SolaTrim would need to be removed and it is unclear if it can be reattached.

What makes for a good animal guard fastener?

Click a topic below to learn more

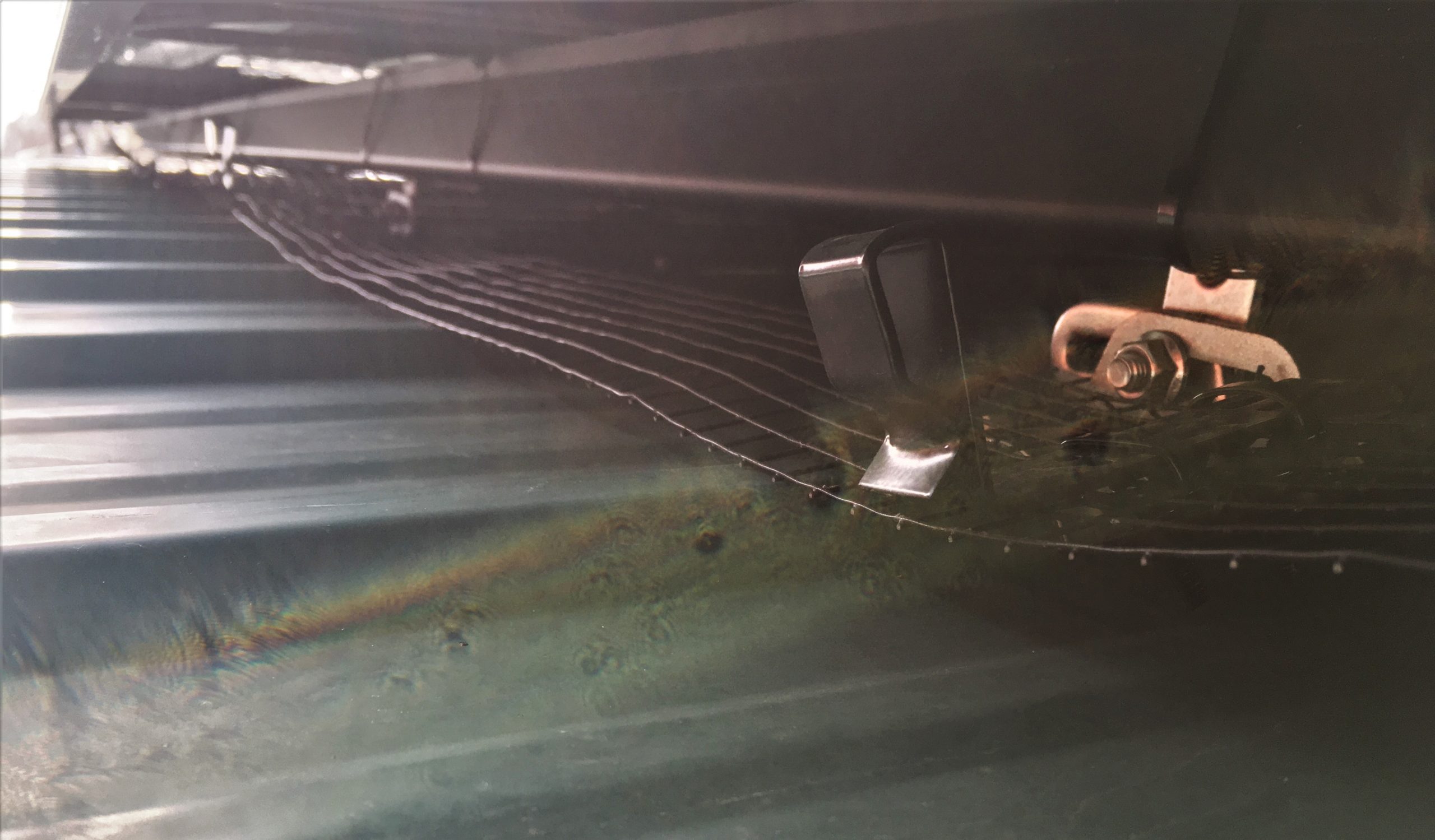

Material & corrosion resistance

In all but the driest, most inland locations, 304 stainless steel and/or aluminum should be used for any fasteners penetrating aluminum racking. This is supported by installer experience, construction industry best practice and PV racking manufacturer recommendations. Note that some grades of stainless steel (e.g. 400 series) corrode when in contact with aluminum module frames and racking. A quick way to tell the difference is to hold a magnet next to the fastener (304 stainless is NOT magnetic). While plain steel electroplated “Tek” screws are easy to find, solar technicians in coastal climates have found their thin zinc coatings aren’t up to the task.

Plastic – even the type rated for UV exposure – is not suitable for continuous outdoor exposure.

Compatibility with roof & PV system

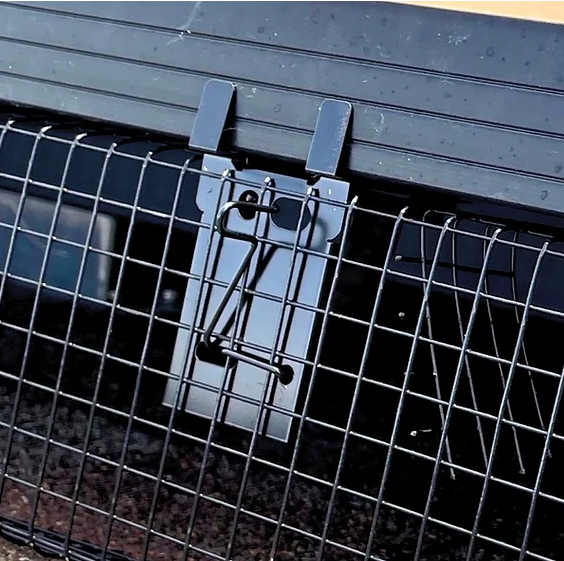

All of the specialty clips listed below are meant to grab onto the solar panel’s aluminum frame. Every model of solar panel uses unique dimensions for the frame, and some clips are incompatible with some frames. Many installers have found this to be a weak point of the SnapNrack clips, which require a deep lip on the PV frame to work. CritterBlok seems to have come up with a clever solution to this with their 2-part clamp design.

Full-support clips vs. J-hooks

Specialty clips generally fall into two categories – Full-support clips and J-hooks.

Full-support clips, like SnapNrack’s old hangers and CritterBlok, suspend the wire mesh above the roof surface and prevent the mesh from being pushed in or pulled out. This makes them a top choice for metal roofs, where the homeowner does not want the mesh touching (and scratching) the roof surface. The risk with these clips is that they can come unclipped from the solar panels due to snow loads or curious animals. We’ve found CritterBlok does a great job of holding on to the module frame, while SnapNrack’s old hangers were not trustworthy.

J-hooks pin the wire mesh to the PV module frame, but require the mesh to rest on and be supported by the roof. They are therefore NOT suitable for metal roofs where roof-to-mesh contact can be noisy and unsightly. The main weakness of most J-hooks is that they rely on a pushnut to grip a “J” shaped wire. Pushnuts tend to be flimsy and susceptible to slippage, so we don’t feel they are appropriate for an installation that must stand up to 25+ years of weather and curious animals. SnapNrack appears to have gotten around the pushnut issue with their new clips, which use a threaded interface instead of a pushnut.

The Best Fasteners for Solar Animal Guard

For the Rail Mount Method

The sturdiest, most affordable and longest-lasting way to attach wire mesh to a PV array is often the Rail Mount Method with self-tapping screws and washers. Slick Tools sells our own special self-tapping screw with a pre-assembled washer for this exact purpose. It’s made of high quality 304 stainless steel and coated black to blend into the racking system. The pre-assembled washer saves time on the roof, where the last thing you need is to be juggling lose fender washers!

A great alternative: CritterBlok

That said, there are plenty of situations where the Rail Mount Method is not possible or needs extra reinforcement, such as:

- Railless racking systems (no rails to attach to)

- Arrays where the rails are set in deep under the panels, making them difficult to access

- Arrays with flush-cut rail ends which cannot be easily screwed into

- Rail systems with integrated wire management, where screwing into the rail could mean piercing wire insulation and is therefore unacceptable

- Some installers just prefer a faster method!

In all of these cases, we recommend attaching wire mesh directly to the PV module frame using CritterBlok™. It’s a game-changing product which offers very secure attachment while allowing easy access underneath the panel should service be required down the road. Learn more at the CritterBlok™ product page!

All Fasteners & Clips

| Product | $/attachment* | Style** | |

|---|---|---|---|

| Slick Tools Black Self-Tapping Screws with Preinstalled Washer |  | $.32-$.55 | Screw |

| CritterBlok |  | $2.30 | Full-support clip |

| My Squirrel Guard J-hooks |  | $0.45-$.80 | J-hook |

| Spiffy Clip |   | $.83 | J-hook |

| SnapNrack Array Edge Screen Clip (new flange bolt style) |  | $1.77 | J-hook |

| SnapNrack Array Edge Screen Clip (old style – discontinued) |  | $1.20 | Full-support clip |

| Omni Clip |  | $1.00-$1.20 | Full-support clip |

**See our notes on J-hooks vs full-support clips

What to look for in cable ties & hogrings

Click a topic below to learn more

Material

While plastic zipties continue to be used throughout the solar industry, they are simply not appropriate for continuous outdoor use on the time scale of a PV system. Do not be fooled by “UV-rated” zipties; while they do last longer than non-UV rated ones, they will break down and crack in the sun after 3 or 4 years.

Stainless steel zipties are a fantastic replacement for plastic zipties. At around 13 cents each, they are affordable enough to easily justify making the switch.

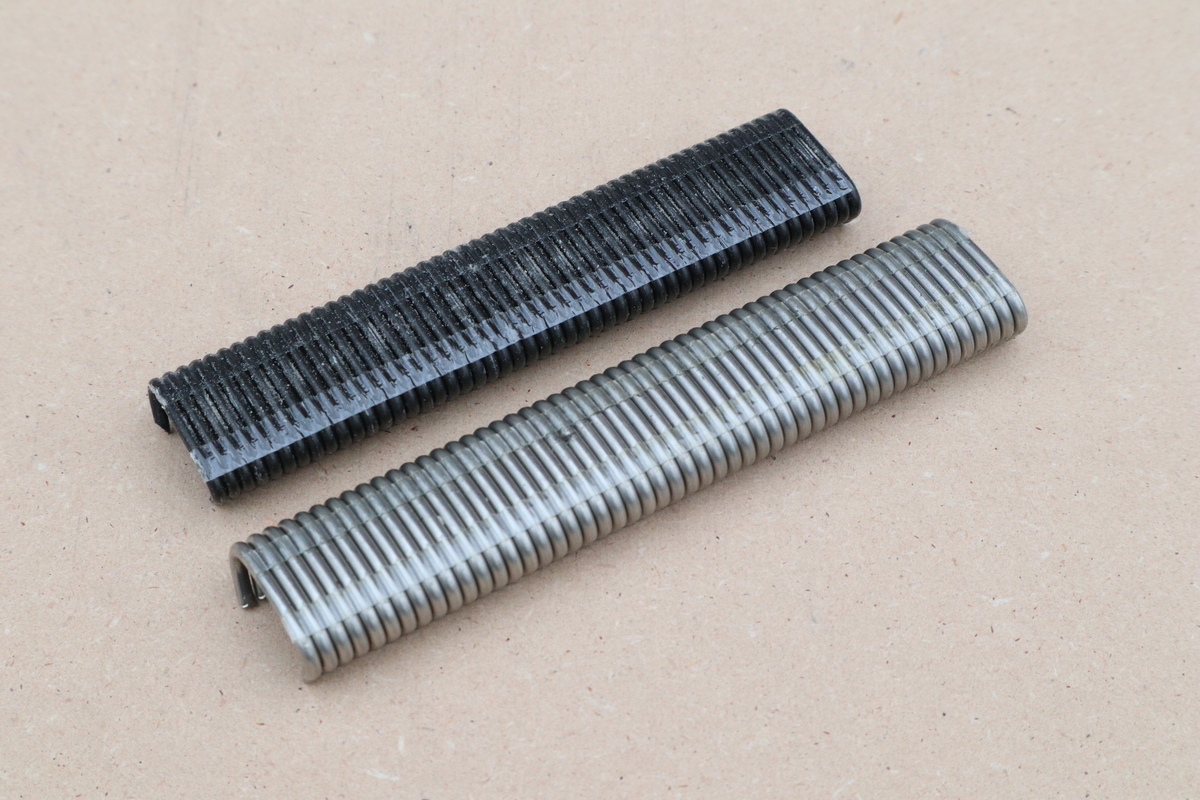

Hogrings are available in a wide range of materials. We recommend stainless steel or coated galvanized steel (which is less rust-resistant, but will last at least as long as the underlying wire mesh due to the hogring’s thicker wire gauge).

Finish

Shiny fasteners will stand out like a sore thumb on an otherwise discreet animal guard installation. Hog rings and cable ties can both be purchased pre-painted black, saving the installer the trouble of spray painting them at the end of a job.

Tool compatibility

There are a number of hogring tools on the market, and each is compatible with only certain size hogrings. Ensure the gauge (e.g. #14 or #15) and size (e.g. 9/16″) match the tool you plan to use.

The Best Hog Rings and Hog Ring Tool for Solar Animal Guard

The high quality hog ring gun sold by Slick Tools has some nice features that set it apart from similar-looking tools, including stainless steel internal parts and a lanyard loop hole in the handle. You can purchase this tool directly from Slick Tools along with discreet, black-coated hog rings. At 1 cent per hogring, it’s easy to justify the up front cost of the ringer tool.

The Best Cable Ties (AKA Zip Ties) for Solar Animal Guard

This style of stainless zip tie will last virtually forever in the sun, has a reliable ball-bearing locking mechanism, and is coated with black plastic so that it will blend in with the wire mesh. 11.8″ (often advertised as 12″) is an industry standard length that will cover all animal guard (and general PV wire management) use cases.

Professional installers seeking a reliable bulk source for cable ties should check out these ones from Cable Ties Unlimited. Contact them for bulk discounts.

Homeowners or installers looking to try out a small quantity can find similar products on Amazon for around 20 cents a piece.

Professional installers will find that a stainless cable tie tensioning and cutting tool saves time and gives a cleaner-looking cut compared to tin snips.

The Best Wire Mesh Forming Tool

Okay, we have to admit – we’re a little biased here, and our only competition is a 2×4! But if you’re going to install animal guard on a regular basis, get yourself an AG Bender. This tool performs the tedious and painful work of bending wire mesh into channels prior to installation – making it a win for safety, efficiency and comfort. Learn more on our AG Bender product page.

The Best Tin Snips for Wire Mesh

Any decent tin snips (AKA dykes) will cut wire mesh, but our favorite are the Offset Max2000 Aviation Snips from Malco. They seem to give you just the right amount of leverage for cutting 19 gauge wire mesh, and the offset cutters make it easy to get deep into a cut without the mesh getting caught up on the handle.

Bit Extensions

Bosch’s bit shank extensions are great for holding your nutsetter bit when you’re reaching far under a PV array to screw into a rail. Their Daredevil QC models (which are labeled for use with spade bits, but work well with any quick change bit) have a locking mechanism that keeps the bit from falling out while you’re working.

Got a question about one of our recommendations? Need advice on a tricky AG situation? Want to suggest an addition or update? Reach out to us through our contact form or the Comments section below. Cheers!