The Contact Rods are the 6 long plastic rods inside the AG Bender. When wire mesh is drawn through the Bender, the mesh slides against these rods and is formed by them.

Teflon vs Delrin Contact Rods

Contact rods come in two varieties – Teflon and Delrin. Each Bender is supplied with one type or the other, but they can be swapped out by the customer depending on the type of wire mesh you are using. Learn more about the different types of wire mesh and contact rods.

Most AG Benders are provided with Teflon Contact Rods, which are appropriate for PVC-coated wire mesh. If you try to process the wrong type of wire mesh for your Contact Rods, you may experience difficulty pulling material through the Bender and accelerated wear of the rods.

Contact Rod wear, rotation and replacement

Contact Rods are expected to wear somewhat with use, as wire mesh slides against them. In most cases this wear is very minor. There is usually a “break-in” period for new rods, where it becomes easier to pull mesh through the Bender for the first couple hundred feet of mesh.

Flat spots

Flat spots may develop on Contact Rods where the mesh slides against them. This usually happens quickly on a new machine, then stops as the rods now have a wider contact area with the mesh, and the abrasive pressure is reduced. Flat spots do cause a slight reduction in the Bend Angle that can be achieved with the Bender. If flat spots become a problem, you may be able to rotate or swap the rods as described below.

Accelerated wear due to improper wire mesh orientation

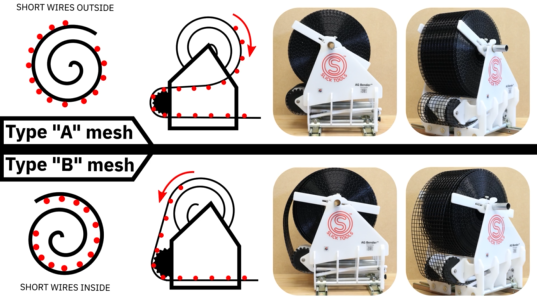

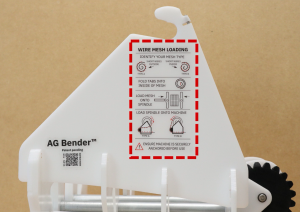

Each roll of wire mesh must be oriented correctly when loading into the Bender. This is a subtle point that can be missed when a new person starts using the Bender. For instructions on how to orient the roll, see:

- The decal on the side of the Bender (in photo below)

- The Bender user guide video (skip to 3m16s)

Loading mesh into the Bender the wrong way can cause wires to cut into the Contact Rods, wearing out the rods and making it harder to pull mesh through the machine. The long grooves cut into the Contact Rod below are evidence of improper mesh orientation.

Dealing with Contact Rod wear

Fortunately, there are good options for resolving contact rod wear:

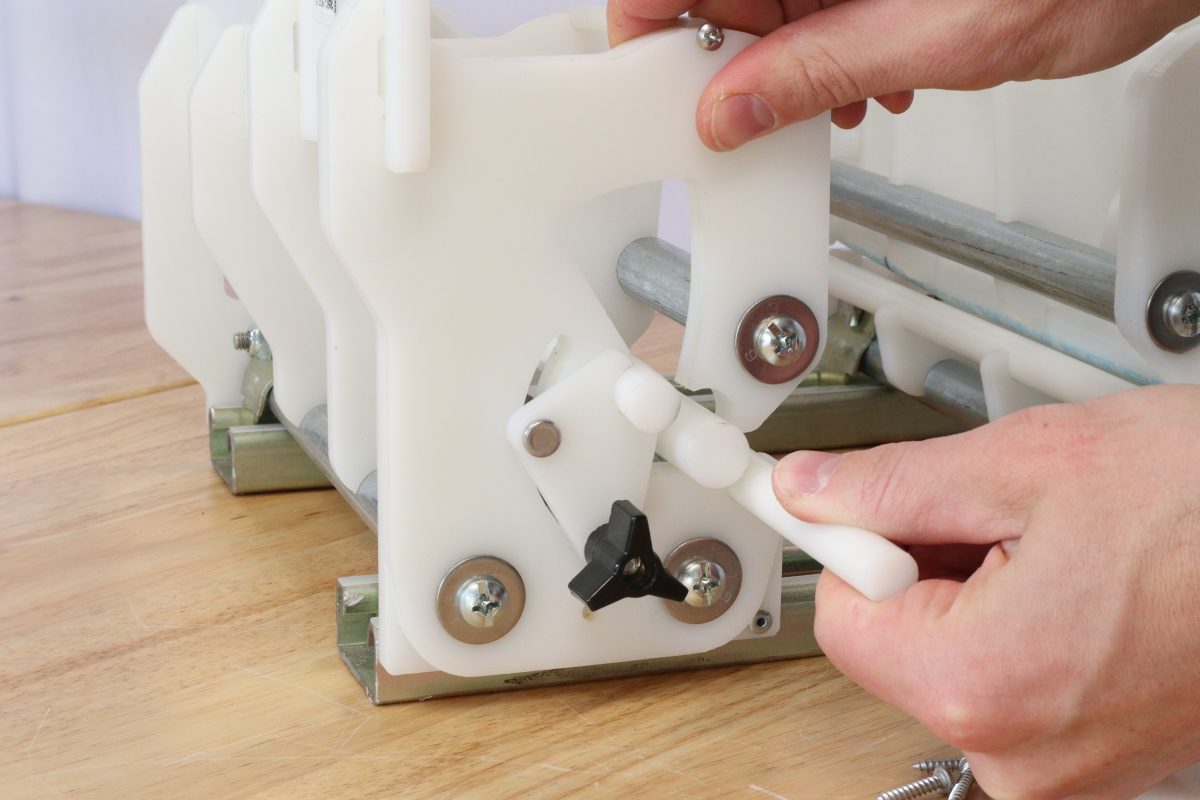

Option 1: Rotate your rods

If you have Teflon contact rods, simply rotate them in place using a pair of pliers. This will move the worn portion of the rods away from the mesh, and expose a fresh portion of rod to the mesh.

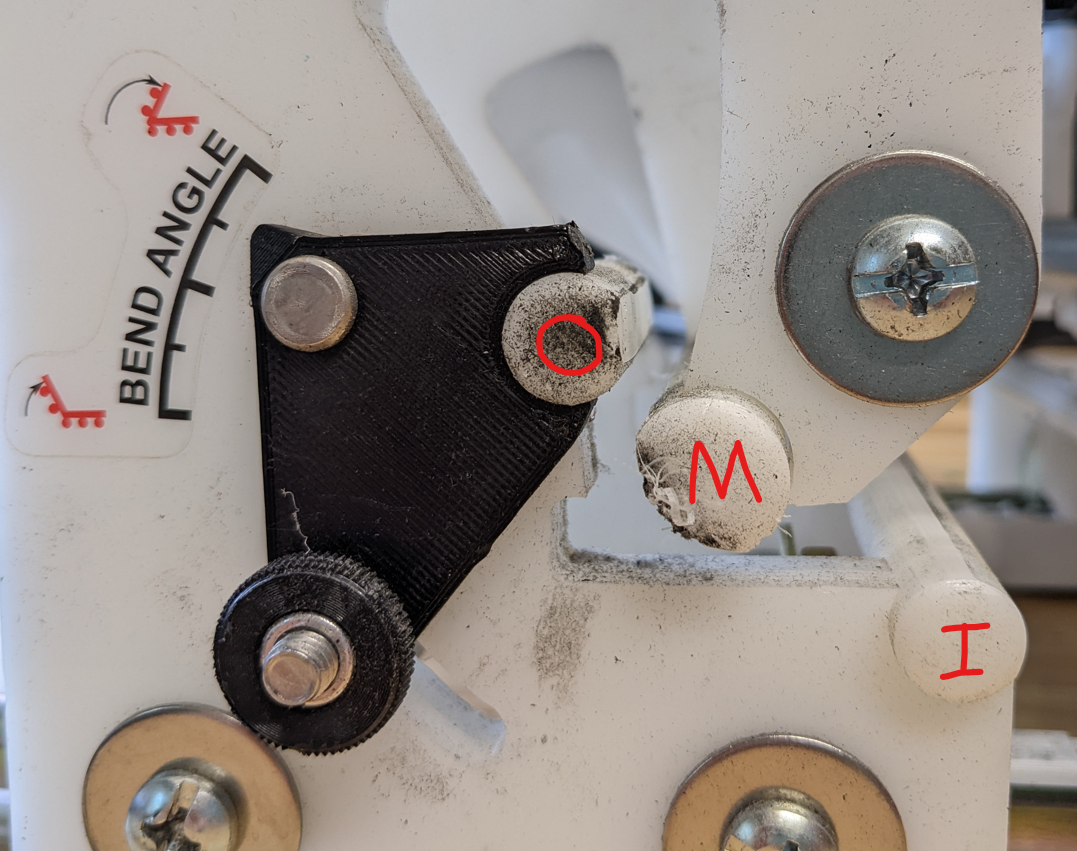

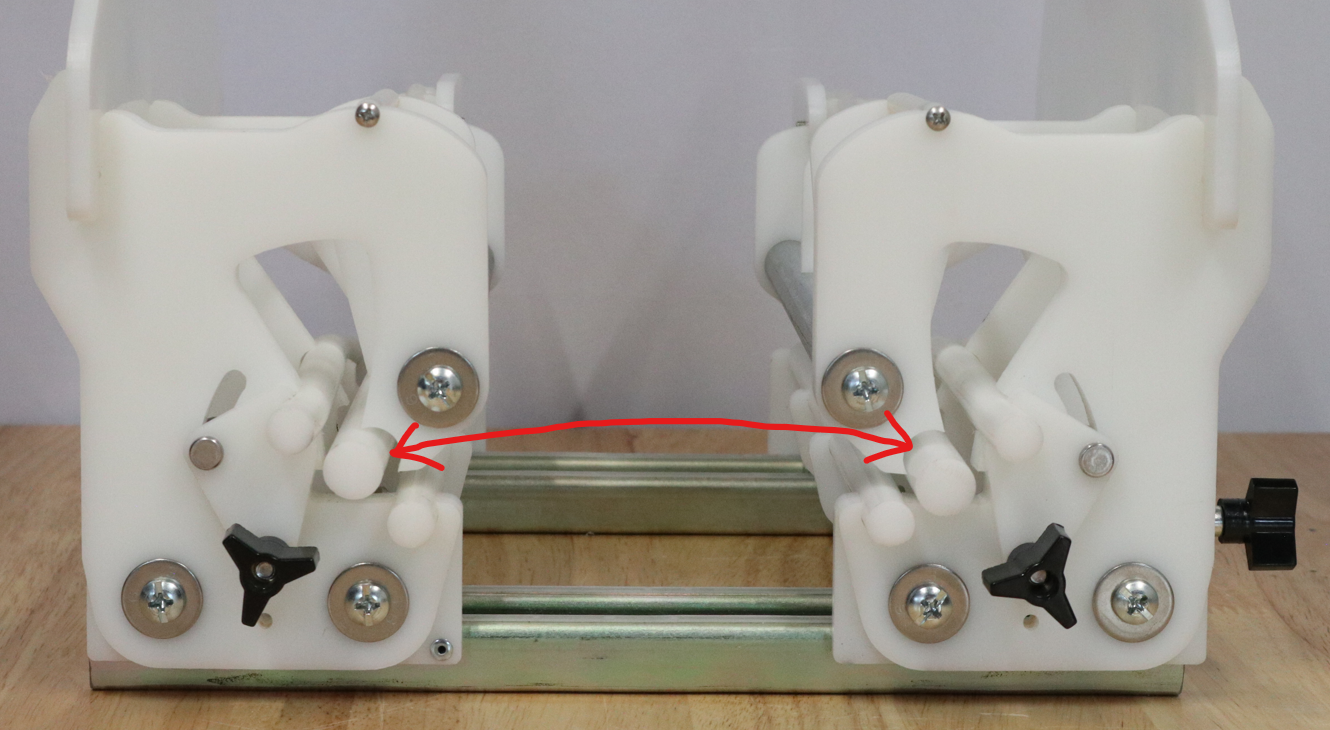

If you have Delrin rods, you can rotate the Inner rods only. The diagram below shows what we call Inner, Middle and Outer rods.

Option 2: Swap left and right side rods

If you have Delrin rods, swapping the left and right Middle rods (shown above) will expose fresh material to the wire mesh. Kind of like rotating the tires on your car.

Note this will work only for Delrin Middle rods. The Outer rods have side-specific shapes and cannot be swapped.

Option 3: Order replacement Contact Rods

As a last resort, you may purchase new Teflon or Delrin Contact Rods from our website. As of writing this article, we have actually never had a customer wear down their rods enough for this to be required, but we are ready if it ever happens!